APPLICATION DESIGN SUPPORT

Once the concept is approved by our customer, prototypes are built and evaluated in our test facilities. This phase often involves design iterations managed by the Plan-Do-Check-Act (PDCA) cycle as defined by AS 9100D and ISO 9001:2015. At the end of this phase, sample products are shipped to our customer for testing and approval.

Approved concepts are then detailed for manufacturing and the optimal production processes are developed using cross functional tools such as Process FMEA and the PDCA continuous improvement cycle. A sales drawing is then released to the customer, showing all the controlled geometrical and performance parameters that are critical to the application.

IGS also offers Design Qualification testing services when required.

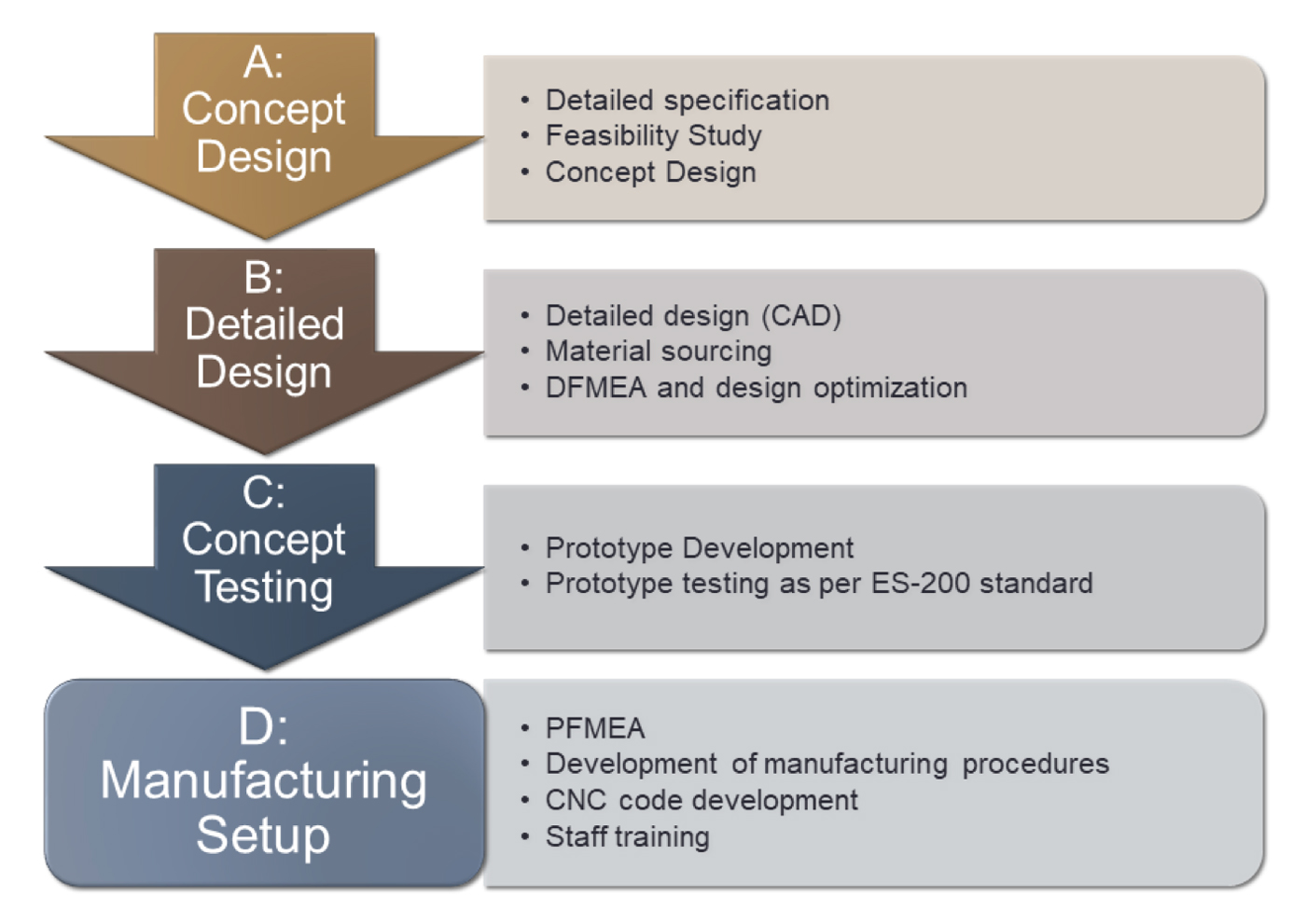

An example of our New Product Development project structure is shown below:

Figure 1- IGS NPD project structure: A report is produced at the end of stages A, B and C for customer review and approval